-

RecebDer Kunde wünscht Sie ihr Produkt produzieren, weil sie mit den Ergebnissen mit Ihren ehemaligen Produktionen froh waren.

RecebDer Kunde wünscht Sie ihr Produkt produzieren, weil sie mit den Ergebnissen mit Ihren ehemaligen Produktionen froh waren. -

SeanGute Teamwork – gute Lieferanten, schnelle Aktionen und gute Leute auf beiden Seiten, die zusammenarbeiten…. Danke.

SeanGute Teamwork – gute Lieferanten, schnelle Aktionen und gute Leute auf beiden Seiten, die zusammenarbeiten…. Danke. -

ChrisDank für genug sich interessieren zu reagieren, denkt anders als und erneuert mit uns – hier wieder bei dieser Gelegenheit, zum dieser Alternative zu finden – viel geschätzt von uns in RnD,

ChrisDank für genug sich interessieren zu reagieren, denkt anders als und erneuert mit uns – hier wieder bei dieser Gelegenheit, zum dieser Alternative zu finden – viel geschätzt von uns in RnD,

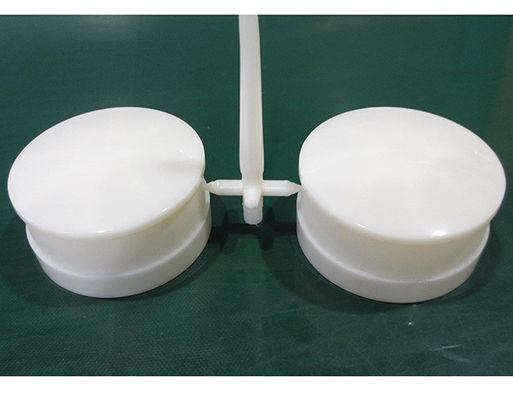

Hochpräzisionsspritzgießdienst mit ±0,01 mm Toleranz und 500.000-1,000,000 Schüsse Schimmellebensdauer für industrielle Anwendungen

| Tolerance | ±0.01mm | Design Software | UG, Pro/E, AutoCAD, Solidworks |

|---|---|---|---|

| Lead Time | 15-30 Days | Shipping | Sea, Air, Express |

| Service Type | Injection Molding Services | CNC Machining | Yes |

| Material | ABS, PP, PC, PA, POM, PMMA, Etc. | Mold Cavity | Single Cavity, Multi-Cavity |

| Hervorheben | ±0,01 mm Toleranz Spritzgießdienst,500,000-1,000,000 Schüsse Schimmellebenszeit Spritzguss |

||

Unsere Spritzgießdienste bieten umfassende Lösungen für die Herstellung hochwertiger Kunststoffkomponenten mit außergewöhnlicher Präzision und Langlebigkeit.,HASCO und DME-Standards, wir gewährleisten eine überlegene Formleistung mit einer Lebensdauer von 500.000 zu 1,0001.000 Schüsse.

- Flexible Form-Hohlraumkonfigurationen (ein- oder mehrfach)

- Erweiterte Entwurfssoftware: UG (Unigraphics), Pro/E (Creo), AutoCAD, Solidworks

- Beibehält enge Toleranzen von ±0,01 mm

- Kapazitäten zur Verarbeitung von Kunststoffen mit vollem Spektrum

- Strenge Verfahren zur Qualitätskontrolle

| Parameter | Einzelheiten |

|---|---|

| Oberflächenbearbeitung | Polstern, Malen, Siebdruck usw. |

| Inspektion | CMM, Projektor, Klemm, Mikroskop usw. |

| Verpackung | Holzgehäuse, Karton, Palette |

| Toleranz | ± 0,01 mm |

| Schimmelpilzleben | 500,000-1,0001.000 Schüsse |

| Entwurfssoftware | UG, Pro/E, AutoCAD, Solidworks |

| Schimmelhöhle | Einzel- und Mehrfachhöhle |

Unsere ISO90001-zertifizierten Dienstleistungen bieten vielseitige Lösungen für verschiedene Fertigungsbedürfnisse in verschiedenen Branchen:

- Automobilindustrie:Präzisionsbauteile mit engen Toleranzen

- Elektronik:Komplexe Kunststoffgehäuse und Teile

- Medizinprodukte:Hochwertige, sterile Komponenten

- Verbrauchsgüter:Dauerhafte Produkte mit ausgezeichnetem Finish

- Verpackung:Maßgeschneiderte Lösungen für verschiedene Anwendungen

Wir unterstützen komplementäre Prozesse, einschließlich Thermoforming, Kunststoffverarbeitung und Thermosetting-Formdienstleistungen für komplette Fertigungslösungen.

Unsere Dienstleistungen bieten eine umfassende Anpassung mit flexiblen Optionen:

- Auswahl der Materialien: ABS, PP, PC, PA, POM, PMMA und mehr

- Mindestbestellmenge (MOQ): 1 Satz

- Flexible Formkavitätenkonfigurationen

- Mehrfache Verpackungsmöglichkeiten: Metallpaletten, Holzkisten, Kartons

- Produktionskapazität: 10 Stück/Monat

- Lieferzeit: 45-50 Tage

- Flexible Zahlungsbedingungen (T/T akzeptiert)

Zu unseren umfassenden Unterstützungsleistungen gehören:

- Beratung bei der Gestaltung von Formen und Materialwahl

- Prozessoptimierung und Fehlerbehebung

- Anleitung zur Einrichtung der Maschine und Anpassung der Zykluszeit

- Qualitätskontrolle und Prüfungen

- Laufende Produktionsunterstützung

Unser technisches Team bietet Ihnen während des gesamten Projektlebenszyklus fachkundige Unterstützung, um optimale Ergebnisse zu erzielen.